A NEW control system has reduced energy use and greenhouse gas emissions from ExxonMobil’s fractionation plant at Long Island Point, Hastings, according to engineer James Curry.

Mr Curry says efficiency and productivity improvements at the plant were achieved by upgrading the dynamic matrix control system (DMC).

“We have upgraded and optimised the DMC system and conducted a comprehensive review of the model settings to ensure we are maximising the value of the molecules that pass through our plant,” he said.

“As a result we have reduced our energy use and greenhouse gas emissions per litre of product.”

Mr Curry said the DMC upgrade was “just one of many diverse projects that help to set the plant up for improved operations well into the future”.

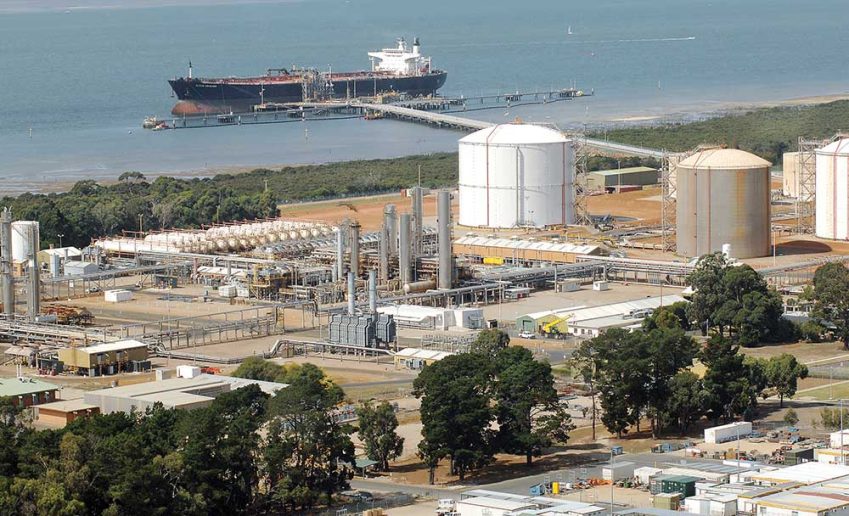

Opened in 1970, the Long Island Point plant plays a vital role in the Bass Strait production line. It carries out the final stage in processing gas liquids – ethane, propane and butane – and stores crude oil before it is distributed to refineries in Australia and overseas.

New plant manager David McCord said he was impressed by what had been achieved by his predecessor, Kim Hahn, and the Long Island Point team over the past year.

“There has been a tremendous amount of work high-grading equipment and facilities from the gate to the quay,” he said. “We have seen well over 3000 work orders completed across our operations.”

Mr McCord said that recent works included 250 pressure safety valves tested and overhauled, a new radio tower that eliminated communication black spots, the new Longford 350 liquids pipeline filled with crude and the old 700 pipeline purged of crude, and redundant pipes and loading arms removed from the jetty.

He said more than 1300 bolts have been replaced, pipes and vessels had been inspected and, where necessary, sand-blasted, repaired and recoated, high voltage equipment upgraded to new technology and new personal protection equipment and procedures in hazard areas.

Other improvements included increased hearing protection for workers, two major compressors overhauled, critical operating parameter (COP) elimination through replacement of reboiler with upgraded materials, propane storage tanks deluge system successfully tested, and traffic control lines repainted around the site.

Mr McCord said there had been two successful major shutdowns in the past 12 months and work was progressing on the plant’s tank farm refurbishment project.

“Our major hazard facility licence has been renewed for another five years and I have to congratulate the team for getting the plant into such great shape for the future,” Mr McCord said.

“For me, being a good manager is not just maintaining projected benchmarks and production levels – it’s about constant communication with the wider team and challenging the status quo to discover how things can be done better.

“Taking an inquisitive approach to your job helps to keep people motivated, engaged and happy. There is nothing like solving a problem and celebrating as a team. That’s what gets me out of bed in the morning.”